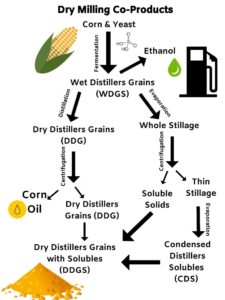

As a consultant in central Nebraska, one of the most common questions I receive is: “Have DDGS changed?” Of course, there is lots of antidotal evidence that ethanol plants are getting more efficient. Plants have improved utilizing all the starch from the corn and removing more of the corn oil. Let’s review the ethanol production process and the resulting co-products (Figure 1).

Dry Milling Process and Ethanol Co-Products

First, corn grain is milled to reduce particle size. This allows for efficient microbial and enzymatic activity in the fermentation stage.

Second, the ground corn is mixed with yeast and fermented. Ethanol plants use sulfuric acid to adjust pH for optical fermentation. This process results in wet distillers’ grains, corn grain with starch removed.

Next, distillation and evaporation separate the ethanol, dry distillers’ grains, and whole stillage.

Then, the whole stillage is centrifuged and soluble solids are separated from the condensed distillers solubles, more commonly referred to as syrup.

The soluble solids are added back to the DDGS. Ethanol plants market the syrup separately as a liquid feed or add it back to the DDGS to increase energy value.

Meanwhile, the DDGS are centrifuged, and the corn oil is removed to be sold separately. Corn oil is marketed as a feed energy supplement or for biodiesel.

Finally, the grain is dried, and the soluble solids and syrup are added back.

Why does the process matter to beef producers?

This is a simplified overview on a complex process. However, it is imperative to understand that as these processes improve, there may be less fat and simple carbohydrates in DDGS. Typically, this means less energy available to the animal. On the flip side, as these components decrease, crude protein and crude fiber increase.

This is good news for producers looking for a protein supplement. DDGS are approximately 50:50 rumen degradable protein and bypass protein. Therefore, as a protein supplement, DDGS benefit rumen microbes. This allows for efficient forage utilization, and provides protein directly to the animal through undegradable intake protein.

Have DDGS changed?

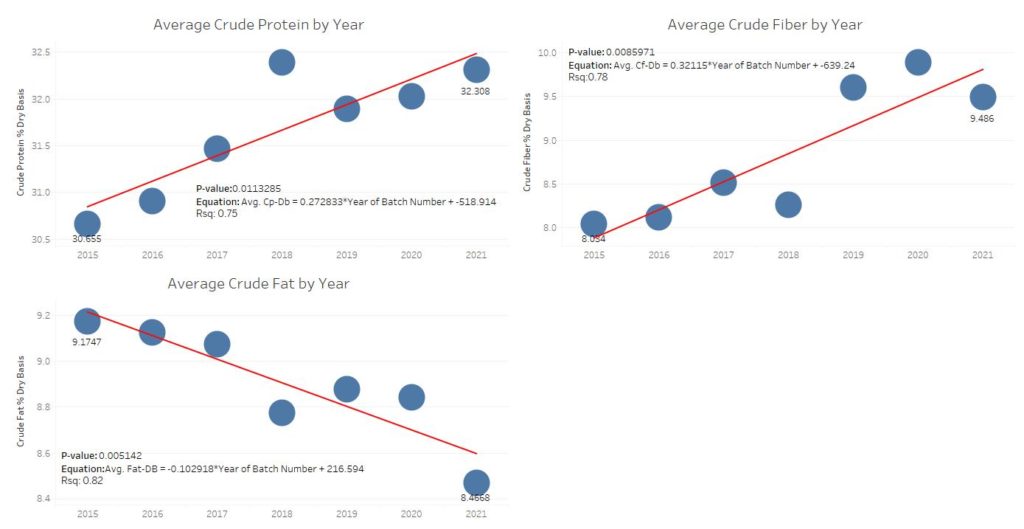

So, have these nutrients changed over the past few years? The answer is both yes and no. I compiled data from DDGS samples submitted to Ward Laboratories, INC. from both producers and ethanol plants over the past 7 years (n ≥ 2057).

First, crude protein on average has increased nearly 2 percent from 2015 to 2021 (Figure 2). Next, crude fiber has also increased over the years by approximately 2 percent on average (Figure 2). Finally, crude fat has decreased by about 1 percent on average. Each of these trends is significant with an R2 ≥ 0.75 and p ≤ 0.01.

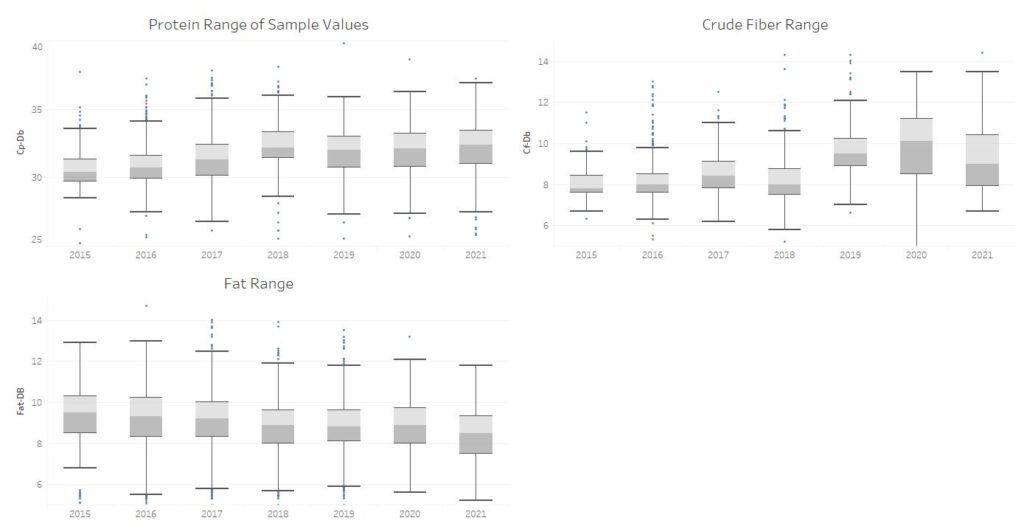

However, while DDGS changed in the average values, does not equate an overall shift in the sample distribution. In Figure 3, we can see that the distribution of each nutrient has not significantly changed over the years. Each nutrient is still highly variable.

In summary, there are trends in the average nutrient values of DDGS. These trends are likely due to improved efficiency in corn oil removal at ethanol plants. However, there has not been a significant change in the distribution of these nutrients. This variability among samples, emphasizes the need to analyze DDGS when balancing beef diets and utilizing distillers’ co-products as a supplement.

Implications for utilization of DDGS in beef diets

Protein and energy supplementation

Therefore, the amount of supplement required for a 35% crude protein DDGS will be less than for a 28% crude protein DDGS. Additionally, the amount of supplement needed will depend on the protein and energy concentrations in the forage being fed and physiological state of the beef animal.

Balancing precise diets based on lab analysis will save on wasted expense for unnecessary feed. Use the protein and energy (TDN) values of DDGS to meet animal nutrient requirements in the most economical way possible. No, wasted feed cost and healthy cattle.

Mineral supplementation

Furthermore, I also evaluated micronutrients. I did not discover any trends in minerals concentrations over the years. Yet, like the macronutrients examined in this article, mineral concentrations are variable across samples. Therefore, it would be prudent to analyze DDGS for macronutrients and minerals.

Moreover, choosing a mineral supplement based on both forage and DDGS micronutrient profiles can prevent animal health issues. Such as sulfur toxicity, which is a common concern when feeding distillers co-products. Additionally, mineral levels in forages combined with DDGS, often show minimal need for additional mineral supplementation.

However, it is important when evaluating these nutrients to consider bioavailability. In forages, minerals are typically available and readily solubilized in the rumen. However, interactions with other minerals and microbial populations my restrict their availability to the animal. Bioavailability of minerals in DDGS appears to be relatively high. When evaluating diets where DDGS is the protein supplement, copper, zinc, and salt are the micronutrients most often requiring additional supplementation.

Concluding, DDGS are a great source of protein, energy, fat, and micronutrients. Our data shows the nutrient profiles of DDGS changed over the years on average. This change is likely due to increased ethanol production efficiency. However, the distribution of each nutrient in samples submitted remains unchanged based on visualization of this data. Due to the variability of DDGS as feed, diligent producers should analyze DDGS loads to ensure proper diet formulations.